Machined to Perfection

The use of high pressure water continues to grow into emerging markets. The growth of your company depends on using quality products with the engineering to perform under the harshest conditions.

The use of high pressure water continues to grow into emerging markets. The growth of your company depends on using quality products with the engineering to perform under the harshest conditions.

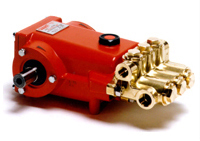

With a German/American background, Giant’s corrosion resistant line pumps not only meet your needs, they also provide solutions that will help your company expand.

What’s Unique about Giant’s pumps?

The gear end of Giant’s industrial pumps are designed and built to last through thousands of hours of operation. Giant regularly services pumps that have been performing reliably for more than years. From deep-forged (not aluminum) crankshafts (instead of machined barstock) to bronze connecting rods and high polish finish on solid ceramic plungers, the pumps manufactured by Giant will provide years of smooth, dependable operation with less wear on fluid end components.

Why Does Giant’s Fluid End Last So Long?

To save time and reduce maintenance costs, it’s important to minimize the changes of fluid end components in the field. That’s why we make Giant’s internal fluid end parts of 316 duplex stainless steel; and our elastomers are made to give you the most reliable performance and longest lasting fluid end life in the industry. Depending on conditions, Giant’s fluid end may be constructed of aluminum-bronze nickel, 303 or 316 stainless steel, duplex steel or titanium.

To save time and reduce maintenance costs, it’s important to minimize the changes of fluid end components in the field. That’s why we make Giant’s internal fluid end parts of 316 duplex stainless steel; and our elastomers are made to give you the most reliable performance and longest lasting fluid end life in the industry. Depending on conditions, Giant’s fluid end may be constructed of aluminum-bronze nickel, 303 or 316 stainless steel, duplex steel or titanium.

Why Giant?

Any company can provide flow and pressure. Giant wants your experience with reverse osmosis pumps to be rewarding. You will know you’ve made the right choice when you use a Giant pump.

Downloadable Resources

- Series P300 Plunger Pump Service Manual

- P400 Series – 22 and 25mm Plunger Pump Service Manual

- P435B and P455B Plunger Pumps Service Manual

- P55W/P56W/P56W-HK/P56HT Pump Service Manual

- LP301A & LP600 Pump Service Manual

- LP122A, LP123 and LP255 Pump Service Manual

Let us help you maintain your Giant pumps with genuine Giant pump parts.